Capacity Requirements for Internal Tasks

Internal tasks are the collective term for all work to be executed in an enterprise that is not directly caused by the units produced or by internal services provided. Internal tasks are only indirectly related to the products and services produced or sold. Examples include:

-

- Management, planning and control work in all areas

- Work of the entire sales-oriented areas

- The entire production planning and control as well as the work preparation

- The work of the personnel department, payroll accounting and the time spent on training and further education

- Work of the functions purchasing, warehousing, forwarding

- Tasks for the further development and operation of the entire information technology as far as it is not a matter of orders of individual areas and thus internal services provided.

- Provision of buildings, company premises, installations, and machines ready for operation

- Administrative work to meet legal requirements.

What these Internal tasks have in common is that they are performed for the capability of the organization to perform at all. Managers decide how much work capacity is to be built up and made available in the form of employees or investment capacity as part of strategic and operational planning.

These capacities must always be included in the overall planning of an organization. This can be explained by the fact that nowadays in all industrial companies known to us, more than 50% of the total personnel costs are incurred for internal tasks.

The difficulty is to create a reliable capacity requirements planning for the areas of Internal tasks. One reason for this is the fact that people in these areas often perform a wide variety of tasks in parallel. On the other hand, only a few companies record time consumption for Internal tasks. This makes it difficult to plan the time requirements. In order to get a better grip on capacities and the cost pool for Internal tasks, we have therefore long recommended that work for Internal tasks should also be integrated into factory data capture. Although attendance time can be measured quite easily using time recording devices, many managers are not even required to carry out this recording for themselves. The work for which the time was spent cannot be evaluated from the presence time recording system.

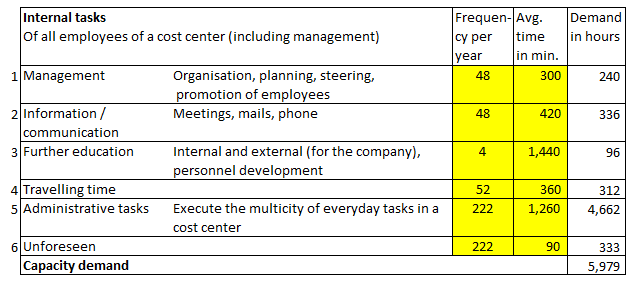

Our experience showed that even the planning of task types in internal areas generates important insights for capacity planning. For this purpose, we divide the tasks into six groups, which occur in almost every cost center:

Task 5 (subject tasks) can be subdivided by cost center. In a sales office cost center, for example, these could be tasks such as addressing potential customers, looking after existing customers, preparing quotations, negotiating contracts. In the personnel department it could be personnel recruitment and selection, wage and social insurances, personnel and illness care, documentation of management and specialist staff potential.

Capacity requirements planning is also an essential prerequisite for Activity Based Costing. For Internal tasks, the direct cause-effect relationship is missing, but capacity requirement estimates can be used to improve the planning quality of fixed costs.

Planning at the level of detail described above benefits the entire company. Since employees are usually reluctant to fill out the activity recording for the actual times incurred, a user-friendly and thus largely automated recording application should be set up.

Thanks to the Lean Production movement impressive improvements have already been achieved in the area of directly product-related services and production management, Now it is important to apply the findings to Lean Administration as well. This helps to improve the cost position towards competition.